About Us Company History

Who are we?

Shepherd Offshore is a family-owned and run business. We’re driven by a desire and passion to invest in the people, communities and economy of the North East.

A developer of infrastructure and strategic property, as well as assets and operator business divisions, we deliver critical support services to the Offshore, Oil & Gas, Energy, Marine, Power and Renewable Energy industries on the River Tyne.

We partner local and global industry with government support; from the responsible acquisition and regeneration of land, to the successful development of world-class manufacturing clusters and residential & commercial projects.

Present in the North East since the 1880s and firmly established in Newcastle upon Tyne by the 1940s, our work continues to make a significant contribution to the growth of our region’s industry.

Our aim is to create value through our strategic platforms, harnessing our entrepreneurial skills to effectively identify and develop opportunities to which we apply our renowned expertise and first-class customer service in a professional, safe and efficient way.

Where did it all start?

Pictured: Charlie Shepherd (second from left) in Kalgoorlie, Australia in early 1900s during Australian Gold Rush, Frederick William Shepherd (centre left, with Charlie and Freddy Shepherd aged 4 & 5 pictured in background) purchasing a horse in Byker, Newcastle

In 1881, Frederick William Shepherd, a general castman, moved to Byker, Newcastle with his wife Sarah and established the company business there, becoming a trader.

In the early 1900s, Charlie Shepherd travelled to Kalgoorlie, Australia to mine the region’s gold fields and returned successful a number of years later.

By the 1910s, the company was firmly established in Byker, Newcastle, trading scrap and materials from their Quality Row site, ran by William Frederick Shepherd and his family. After William Frederick Shepherd’s return from the First World War, the company was run by Charlie Shepherd and his wife Catherine and expanded to include transporting materials.

Throughout the 1920-30s, Catherine and her sons (Freddy, Charlie and John) began to grow the business in Byker and Newcastle. Catherine became a significant driving force, supporting her husband and her sons in developing a regional company and modern outlook.

In 1939, Charlie Shepherd joined the British Army, fighting in mainland Europe during the war and being part of the Dunkirk evacuation in 1940, then being redeployed to North Africa, Italy and other areas of Europe. When he finally returned home in 1945, he became the driving force in building the CH Shepherd & Transport company through hard work and dedication.

Pictured: Catherine Shepherd, Charlie Shepherd in British Army in 1939, Vickers-Armstrong Walker Naval Yard

Pictured: Charlie Shepherd in British Army, Charlie and Mona Shepherd, founders of C H Shepherd & Sons Transport

Founded by Charlie and Mona Shepherd, the company was incorporated in Byker in Newcastle’s East End in 1946. In that year, general haulage and transport company C H Shepherd & Sons Transport – proud owners of 15 vehicles – branched out from Shepherd Scrap Metals, which had been in operation as the core family business for over 50 years.

The transport company moved a variety of goods from the North Shields Fish Quay & Newcastle Quayside down to the bustling markets of London.

The company’s clients consisted of the National Water Company, a range of food suppliers, and the shipyards on the River Tyne, including Swan Hunter and the Walker Naval Yard & Brewery. The company regular serviced vessels on the Newcastle quayside day in and out.

Pictured: Mr & Mrs C H Shepherd, C H Shepherd and family emigrating to Australia, C H Shepherd & Sons Transport on Newcastle Quayside

The 1950s brought significant change for the company. The Shepherds immigrated to Australia and sold their transport business to the government, which then nationalised it. Whilst in Eastern Australia, C.H. Shepherd worked on the country’s railways, returning to the UK in 1957. Upon their return, C. H. and Mona Shepherd bought their company back from the government and increased the number of vehicles in their fleet to 20, which heightened their goods transports to over 1,000T per year.

The company’s regional business focus attracted perishable goods clients from the Newcastle Quayside and Green Market as well as larger companies, including British Paints, National Water Companies, Newcastle Corporation, Metal Box and the Consett Iron Company.

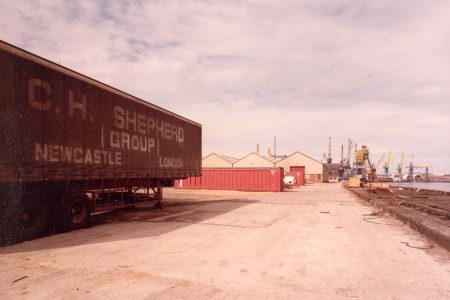

Pictured: Transport & Petrol Company in Byker Newcastle, C H Shepherd & Sons Transport, Border Shepherd vessel, Mercantile Dry Dock Co Ltd, North East Marine

The 1960s saw C.H. Shepherd and Sons – Freddy and Bruce – double their fleet to 40 vehicles, and extend their routes nationally. The company also diversified into the management of storage warehouses and petrol stations, selling around 1 million gallons of fuel a year.

Freddy Shepherd served his apprenticeship at Swan Hunter’s Neptune Yard. He later went to sea, working around the world on the Border Shepherd for Common Brothers Ltd. After a number of years away, he returned to Newcastle and joined the family business.

Clients in the early sixties included National Transport and Storage Swan Hunter, North East Marine, Naval Yard Walker, the Fruit Exchange Spitalfields, Covent Garden, Parsons, BTR Group and Newalls INS, Commercial Plastics.

Later in the decade, the company expanded and opened its first London office in Covent Garden, with operations dedicated to transport and, for the first time, shipping.

Together Freddy, Bruce and their father applied their combined knowledge of the shipping industry and ignited the flow of business, dealing with shipping requirements on the Tyne with their 40 vehicles, which travelled between Newcastle and London every week. This new trade fed into the company’s established storage and haulage business.

Pictured: Material Management & Distribution Centre, C H Shepherd & Sons Transport fleet, Support Cranes

In the 1970s, Shepherd Offshore expanded again, adding cranage to its portfolio of transport and storage services. The company began to attract clients from the Oil & Gas and Offshore industries, providing streamlined, just-in-time transport and services to clients including Press Offshore, Charlton Leslie, RB Charlton and Swan Hunter.

Pictured: First involvement with Offshore industry, C H Shepherd & Sons Transport & Storage, White Street Materials Management Centre

Additional expansion into new warehousing and storage capabilities attracted more clients from the Oil and Gas sector and, when the company’s Materials Management & Distribution Centre purchased the White Street site in Walker, Shepherd added Conoco, British Gas and Parsons Power Stations to their impressive client base.

With ownership of over 50 vehicles, a fleet of cranes and 250,000ft² of warehousing by the end of the decade, Shepherd Offshore also owned 15 acres of operational land. By 1975, the company was providing services and support to the North East Marine for Oil & Gas clients, including Howard Doris and later Press Offshore, Charlton Leslie, BTR and Amec.

Pictured: Decommisioning of Walker Naval Yard and North East Marine cranes by the company

Pictured: Vessel and rig at Offshore Technology Park, Offshore Technology Park development, original Offshore Technology Park office, Shepherd Offshore Storage & Transport

In the 1980s, Shepherd Offshore worked with major Oil & Gas, as well as fabrication companies including Press, Charlton Leslie and Howard Doris Ltd. By integrating into supply chains, the company provided added value to clients such as Marathon Oil and BP, Shell, British Gas, Agip, Luk Oil and Bechtel.

Key company milestones during this decade included:

- The decommissioning of Vulcan and Valiant (top sides & jackets).

- The provision of airfreight to Kazakhstan, chartering flights, shipping and transport, as well as staff.

- A secured contract working for Hamilton Bros (Oil and Gas) to operate onshore supply bases at Blyth and Liverpool Bay and employing over 100 people.

- The operation within the region for the Oil and Gas industry at Amec, Conoco, Philips and Marathon Judy Joanne Tops sides.

Pictured: Shepherd Offshore Storage & Transport, Howard Doris Vulcan Legs

Milestones specific to the company’s Walker site included:

- The provision of over 30 staff for British Gas, running their onshore supply base and support services in Walker from 1984-1995.

- A secured contract with British Gas Materials Management Centre, providing personnel while supplying and managing equipment for the North Sea, Europe and Russia via road, rail, air and sea.

Between 1985 and 1986, Shepherd Offshore was involved in the strategic purchase and consolidation of three former shipyards in Wallsend – the North East Marine, Charlton Leslie’s and the Wallsend Slipway. The company strategically bought 80 acres of land and formed one major yard, demolishing a number of assets & infrastructure, including dockside cranes. The dry docks were filled in and slipways dismantled to develop a yard for the oil and gas industry and offshore construction market. This land was then sold to Press Offshore, igniting significant job creation along the Tyne.

Pictured: Uncle John Dive Support Rig, Heavy Load Transport, rig at Offshore Technology Park, launch of HMS Ark Royal R07

In 1986, Shepherd Offshore was asked to partner with Newcastle City Council in supporting the regeneration of the former Armstrong Naval Yard in Walker. Shepherd Offshore ran the facility and supported the development of the area, renaming the yard the Offshore Technology Park (OTP). This partnership formally marked the start of Shepherd Offshore’s commitment to responsible regeneration and bringing jobs into the region, while revitalising the once-great shipyards along the Tyne.

Pictured: Shepherd Offshore Storage, Bar Protector at Offshore Technology Park, Energy Minister visit

Also in 1986:

- The company’s new responsible regeneration strategy attracted the first Oil and Gas manufacturer to the Offshore Technology Park – umbilicals company Dunlop Armour Line.

- A new facility was built and managed for BT Marine’s cable laying operations.

- The Energy Minister, Peter Morrison, visited the newly refurbished and reopened Offshore Technology Park.

- The Bar Protector became the first vessel to visit Offshore Technology Park.

- The first vessel jack up was completed at the Offshore Technology Park – a mobilisation for the BT marine discovery vessel, Uncle John.

- Between 1986 and 1988 a new client base was established at the Offshore Technology Park, which included Rockwater, Acergy, Brown & Root, SMIT, Siapem, CoFlexip Stena, Bridon, and The Royal Navy

- In 1989, Shepherd Offshore bought and operated the Blackett Charlton pipe fabrication company, which employed 70 people. The facilities on the Tyne, Walker supplied the yard’s construction companies, and Blackett Charlton was then bought back from the group in 1992 with a successful order book.

Pictured: Wellservicer at Offshore Technology Park and Global Producers III at Swan Hunters, construction of Largs Bay in Dry Dock, Offshore Technology Park South Quay, rig and vessels at Offshore Technology Park

- 1990 saw the growth and merger of Dunlop and Coflexip at the Offshore Technology Park. The joint venture, with capacity and development plans supported by Shepherd Offshore, saw the creation of the DUCO venture between Dunlop and Coflexip at Walker Riverside in Newcastle.

- In 1992, Shepherd Offshore buy the Mercantile Marine Ship Yard on the River Tyne in Jarrow, developing and operating the site as a supply base for Brown Root Siapem and EMC. The 11-acre site was remediated and its dry docks filled to create a developable platform. Cemex, the world’s largest concrete manufacturer, currently occupies the site.

- In 1993, Freddy and Bruce Shepherd buy the Mitford Estate in Morpeth, Northumberland. The Estate is home to one of the first private residences designed by John Dobson, built in 1828, and comprises 5,000 acres of rural real estate encompassing 50 houses and seven farms.

Pictured: Reel modifications, Materials Managment Centre, Lifting team, SO personnel

- Between 1993 – 95, Shepherd Offshore bought offshore company Charlton Leslie and successfully provided specialist pipework for the Oil & Gas industry working at Amec Wallsend on Marathon, Concoco Philips and Judy Joanne top sides. After a number of successful years of operation, the company was bought from the group by Fabricom (UK) Ltd.

- 1993 also saw the start of the first phase of restoration at The Mitford Estate in Morpeth, Northumberland. Freddy and Bruce Shepherd authorised a large-scale, six-year programme of restoration and modernisation to begin the preservation of the Mitford Castle ruins, in partnership with English Heritage. Additionally, the Mitford Hall was completely refurbished and modernized.

- In 1994, Shepherd Offshore’s Bruce Shepherd entered into a partnership with Swan Hunter’s Jaap Kroese. The 1994 – 2005 partnership supported the development of the Swan Hunters yard and provided support services for the AllSeas vessel, “Solitaire” – at 1000ft long, the largest pipe-laying vessel in the world – the FPSO Global Producer for Kerr McGee and saw the MoD award the build of two Royal Navy Vessels. Bruce Shepherd’s partnership saw the provision and employment of up to 400 personnel at any one time, including manpower from scaffolders to pipefitters.

- In 1995 Shepherd Offshore bought Metnor Scaffolding Ltd, resulting in an expanded service proposition and the employment of hundreds of personnel at Amec – across jobs such as Marathon, Conoco Philips, Judy Joanne and even at the Ministry of Defence at Rosyth.

Pictured: Shepherd Offshore personnel

- In 1996, Bruce Shepherd and Shepherd Offshore played a key role in attracting Gordon Chapman, the Chairman of Wellstream, to Newcastle. Following a meeting in Panama, Wellstream agreed a strategy of locating and building a flowline manufacturing centre at the Offshore Technology Park on the River Tyne. The factory was built, with a production capacity of up to 240 kilometres of pipeline each year, all of which could be made in Walker, Newcastle. Bruce Shepherd announced that he was “proud to confirm the commitment of Wellstream to establish a major manufacturing base supported by Shepherd Offshore”.

- In 1999, the Offshore Technology Park saw the Construction & Redevelopment of the South Quay. Over 200m of quay frontage and adjacent storage area was constructed, adding significant capacity for Shepherd Offshore’s clientele.

- Also in 1999, 45,000ft² of new manufacturing and office facilities were developed and built at the Offshore Technology Park for clients Duco Ltd and Co-Flexip Stena.

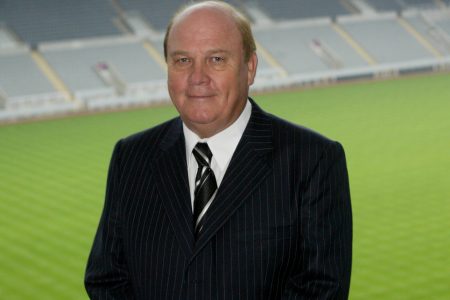

Pictured: NUFC, NUFC redevelopment, W F Shepherd at NUFC stadium, Champions of First Division, Princess Diana visits Newcastle

Pictured: Operations at Offshore Technology Park and Neptune Energy Park, W F Shepherd on quay

- The 2000s saw Shepherd Offshore form a second, world-class manufacturing cluster on the River Tyne in Newcastle, with the redevelopment of the Neptune Energy Park (NEP). The site was bought between 2007 and 2011, and secured over 100 acres of former shipyard land and surrounding areas, putting plans in place for the creation of jobs for the local community – and beyond.

- Also in 2007, Bruce Shepherd worked in partnership with the Princes Trust at the Mitford Estate, with the aim of raising more than £1m to support the charity’s work to help change the lives of disadvantaged young people in the North-East.

- In 2008, the Shepherd Offshore board agreed to back and support the government’s River Tyne North Bank Study, with its focus on responsible regeneration. The study’s mission was to create a world-class infrastructure, support the creation of jobs and attract manufacturing back to the River Tyne.

Pictured: Shepherd Offshore personnel

- In the same year, Shepherd Offshore bought the former Amec Yard in Wallsend, which had previously been the Press Offshore Yard, with the aim of significant job creation.

- Between 2008 – 2009, Shepherd Offshore developed the former Brims construction site in Wallsend, creating 89 houses in a joint venture with Bellway as part of the company’s regeneration strategy.

- In 2009, Freddy Shepherd bought the Northern Constitutional Club in Newcastle’s City Centre. The purchase was made strategically, in the hope of supporting development in the area.

Pictured: Operations at Neptune Energy Park and Offshore Technology Park

- In the same year, the company acquired the 26,000 m² site of the former school, La Sagesse, which sits in 10-acre grounds In Jesmond, Newcastle.

- Between 2008 and 2012, remediation began across 100 acres of land at the Neptune Energy Park to ready the site for construction and development. Over one million tonnes of soil and materials were remediated, preparing the platform for development, and re-establishing the legacy of the shipyard.

- In 2009, Shepherd Offshore announced that the BBC would be filming 13 episodes of popular children’s programme Tracy Beaker Returns at La Sagesse in Jesmond.

Pictured: Jesmond Towers Estate development, W F Shepherd at NUFC, Charles Shepherd & Daniel Thompson, Neptune Energy Park remediation, W F and B S Shepherd, spooling to Seven Arctic

Pictured: Offshore Technology Park during 325T HH Crane upgrade, construction of Gravity Bases for Blyth Wind Turbines, W F Shepherd, Neptune Energy Park, operations at Offshore Technology Park

- In 2010, MV Opus was the first vessel to arrival at Neptune Energy Park. The vessel discharged blade moulds for 74m wind turbine blades, needed by Clipper. Once the moulds were offloaded, via tandem lift, the Shepherd Offshore team completed a complex lifting and handling operation.

- Between 2010 and 2013, Shepherd Offshore developed the former Northern Electric site in Wallsend – known as ‘The Covers’ – for housing. The project, working in conjunction with Bellway Homes, created 127 new houses in a two-phase development strategy.

- On 18th Feb 2010, Prime Minister Gordon Brown opened the Neptune Energy Park. The visit coincided with start of the construction of the Clipper Wind Power building and site facilities at the Park. In the same year, Shepherd Offshore built a bespoke building for James Dehlsen, CEO of Clipper Windpower, capable of manufacturing blades at a length of 72m. The building covers approx. 52,423ft² with the area developed and construction completed within a 10-month period, and at an overall cost of £8 million.Prime Minister Gordon Brown said: “I am really proud of the effort that has been put in by Shepherd Offshore and Clipper, along with One North East, to bring these new green jobs to the East of Newcastle”.

Of the Project, Freddy Shepherd said: “Today is a very important day for us and we believe it is a very important day for the city of Newcastle, the North East and the country”. - Further North, in Scotland, the Shepherd Offshore board bought The Halbeath Interchange, near Dunfermline, in 2010. The site, situated a mile from the Forth Road Bridge, was originally developed for semiconductor manufacturing and, with adjacent land, covered a total of 150 acres. The 93,000m² building had been vacant since 1998 and, whilst serviced and partially fitted-out, had not been completed, offering a variety of opportunities for alternative and re-development.

- In the same year, four 90m concrete structures were successfully constructed in the Neptune Energy Park Dry Dock by Bouygues Travaux Publics and sailed away for use in Tyne Tunnel 2.

- In 2011, Shepherd Offshore Chairmen Freddy & Bruce Shepherd, Bridon Chief Exec Jon Templeman & Deputy Prime Minister Nick Clegg announced Shepherd Offshore’s building of a new state-of-the-art facility for the Bridon Group at Neptune Energy Park.

- In 2011, remediation of the Halbeath Interchange was approved. The preparation of the site to allow redevelopment included the demolition of the main microchip factory, due to its specialised configuration and as such restrictions to further users.

- Between 2011 and 2014, Shepherd Offshore supported TechnipFMC in the major expansion of their manufacturing capabilities. Shepherd provided over 9 acres of remediated land for development in the construction of a world-class vertical helix assembly machine (VHAM) and extrusion line at Offshore Technology Park, dismantling and relocating vital and existing facilities.

- Permission was also gained to fill three dry docks and reclaim the land, as the resulting modern industrial space would allow further tenants to base themselves on the banks of the river. This move followed Clipper’s decision to locate there.

- In 2012, the Shepherd Offshore board looked to work with all stakeholders for the Halbeath Interchange site, two thirds of which was earmarked as a location for a potential new college, as well as 500 homes. The remaining third was designated as a potential site for industry and education.

Pictured: Shepherd Offshore personnel

- In the same year, the producers of Tracy Beaker Returns at the BBC returned to film another season of the programme at La Sagesse.

- In 2012, Freddy Shepherd announced plans to turn the historic La Sagesse site into one of the North East’s most exclusive housing complexes. Sixty private dwellings – apartments and houses – were proposed for the site as part of a multi-million pound development. Mr Shepherd said the development could create up to 250 jobs and would help preserve Jesmond Towers and the surrounding 13 acres of land.

- In 2012, Neptune Energy Park was recognised as a Local Enterprise Zone (LEP), and awarded Local Enterprise Status for its successful development of the Marine and Subsea sector, along this part of the River Tyne. The development was reported to be well placed to take full advantage of the Enhanced Capital Allowances incentives.

- In 2012, Shepherd Offshore entered into a partnership to design and build a state-of-the-art training centre for Renewable Energy training at Newcastle College. The 20,000ft² Energy Academy facility is strategically positioned on Wallsend, Hadrian Rd.

- In 2012, Shepherd Offshore entered into a partnership to design and build a state-of-the-art Research and Development Centre for TechnipFMC Umbilicals. The 19,677ft² facility is strategically positioned above the Offshore Technology Park in Walker, Newcastle.

- In 2012, Bridon International co-located within Neptune Energy Park, with Shepherd Offshore building a bespoke 85,896ft² manufacturing facility with capacity to produce up to 700 tonne reels. The facility has a total cost to build and fit out of over £30 million. The project brought a further 9000 tonnes of increased rope manufacturing capacity to the NEP, securing over 150 jobs and creating a further 50 positions.

- In 2012, Minister Michael Fallon and Nick Brown MP opened the new Bridon Facility. The manufacturing facility was expected to develop the world’s largest ropes for offshore use – a true global leader. Bridon Chief Exec Jon Templeman said “I’m proud to announce today that Bridon Neptune Energy Park facility is open for business on Tyneside, thanks to the support and ambition of Shepherd Offshore”.

- In the same year, Shepherd Offshore’s 250T hammerhead crane at the Offshore Technology Park was upgraded to SWL 325T. The new 325T hammerhead crane was designed in conjunction with Konecranes and Des Cad. The actual works took over 6 months; modernising the crane and its mechanical and operating capabilities to create much needed capacity and allowing for the development & expansion of our clients’ product ranges.

- In 2013, the Shepherd Offshore office relocated to a new modern facility on Rendle Road. The new office space was built by Elliott Associates as part of the Technip Newcaflex deal.

Pictured: Launch of Clipper Blade Manufacturing Centre, pre-lashing reel before loading to vessel, Hammerhead crane offloading reel from vessel, Hammerhead crane loading reel to vessel, CC4800 Crawler Crane lifting reel from SPMT

- In 2013, Shepherd Offshore invested in a heavy load out platform with a 700mt lift capacity. The platform, measuring 27m x 36m, allows a blanket load of up to 7300mt and provides a critical gate way to all users of the Neptune Energy Park facility.

- A capital dredge programme at Neptune Energy Park was completed in 2013, and currently allows up to 9m below chart datum to be achieved. This provides a vital gateway to all users to and from the River Tyne, and future-proofed capacity for Shepherd Offshore.

- In 2013, Shepherd Offshore completed the sale of La Sagesse with planning for development to David Wilson Homes, part of the Barratt Group.

- In 2013, the vessel, Fugro Symphony, became the 2,000th vessel to visit the Offshore Technology Park in Walker. It carried out project ‘valiant causeway’ from Technip Umbilicals, and a spooled load-out from TUL factory carousels C&F.

- In 2013, Shepherd Offshore purchased the Palace of The Arts with the aim of refurbishing the facility, and bringing it back into use.

- In 2013, Freddy & Bruce Shepherd acquired the Palace of The Arts in Exhibition Park to save the historic building from being demolished. They invested approximately £2 million in its refurbishment the following year, replacing the windows, restoring the original flooring and carrying out maintenance to transform the venue.

- In 2014, Shepherd Offshore developed a new design & build office and manufacturing facility for Royal IHC. The facility covers 41,444 ft.² unit and is used for the design and manufacturing of electro-hydraulic systems for the subsea, marine and offshore industries.

- Shepherd Offshore acquired the site of the world’s first power station to supply three-phase electrical power, which closed in 1915. Following the acquisition, the building was restored, while the adjacent land was remediated and is now available as a development opportunity.

- In 2014, a concept masterplan was submitted for a brownfield site at Halbeath Interchange in Fife, Scotland. The masterplan formed the basis of a Planning Permission in Principle application to the council and was created in close collaboration with the local council and community. Click here to find out more about the project.

Pictured: Operations at Neptune Energy Park and at Offshore Technology Park

- The same year, Shepherd Offshore secured a new partnership with Newcastle University to develop Tyne Subsea, a specialist facility dedicated to providing pressure testing services to a variety of industries across the globe. This facility, built in Neptune Energy Park, is the first of its kind in the UK, bringing together industry and academia in a world-class engineering research facility.

- In 2015, planning permission in principle (PPP) was received for a masterplan providing 225 homes to the Halbeath area.

- In 2015, the GE Innovation Centre for GE Oil & Gas was developed in Neptune Energy Park. The centre houses a suite of testing equipment for flexible pipelines, mimicking the underwater conditions of some of the world’s harshest offshore environments.

- Between 2015 and 2016, Freddy & Bruce Shepherd attracted Wylam Brewery to the Palace of The Arts as a permanent tenant to the regenerated building.

- In the same year, Shepherd Offshore purchased the CC4800 Crawler Crane, which has a useable radius of 472T at 28m and a maximum lift of 800T. The crane is positioned on its dedicated heavy loadout platform at Neptune Energy Park but can track around the facility providing lifting support throughout.

- Between 2015 and 2017, Shepherd Offshore provided the dry-dock and other facilities at Neptune Energy Park for the production of five wind turbine gravity bases by BAM Nutall and BAM Infra. Click here to find out more about the project.

- In 2016, Shepherd Offshore announced its support of the creation of a new Fife College campus in Halbeath, Scotland.

Pictured: W F Shepherd at the Palace of Arts, W F & B S Shepherd, Charles Shepherd & Daniel Thompson, Soccer Aid 2018

- In 2016, Shepherd Offshore completed the design and build of a new office and administration development for TechnipFMC Umbilicals. To find out more about the development, click here.

- In 2017, Bruce Shepherd was made an OBE for services to the economy and skills in the offshore sector. In his own words, “it’s a great honour to receive this, but it isn’t just for me, it’s for the work that’s happened on the banks of the Tyne over the last 20 years.”

- In recognition of their services to the city, both Bruce and Freddy Shepherd were bestowed with Freedom of the City, the highest honour Newcastle upon Tyne can give.

- Also in 2017, Shepherd Offshore partnered with global cable manufacturer JDR Cables, investing £3 million in the design and development of a 28,000 ft.² office and manufacturing facility for the company at Neptune Energy Park.

- In the same year, Shepherd Offshore purchased the former Blackett Charlton site in Walker, Newcastle. The site will be developed as part of the North Bank Strategy, providing responsible regeneration to the community’s requirement.

- In 2018, over 70 vessels arrived at the Offshore Technology Park and Neptune Energy Park facilities to benefit from Shepherd Offshore’s services.

- In October 2018, it was announced that Soccer Aid for Unicef, a charity football event first formulated by Freddy and Lorelle Shepherd, had raised £6.7million in the 2018 campaign. To find out more, click here.

- In the summer of 2019 alone, operational quantities included 16 vessels berthed at OTP and NEP, over 70km of umbilicals/flowline spooling, 30 reels loaded to vessels and transport (max weight 327T) with a total of over 5,000T load-out tonnage and 40 reels discharged from vessels and transport (max weight 241T), with a total of over 1,700T load-in tonnage.

Pictured: Royal IHC development, Newcastle University’s Tyne Subsea, construction for Bridon-Bekaert, TechnipFMC office development, JDR Cables development

- At the end of the Operational Year in April 2019/2020, the Company berthed 99 vessels at OTP & NEP, Spooled 135km Umbilical/Flowline, Loaded 104 Reels to transport (max weight 368T) with a total tonnage o f over 23,000T and Offloaded 88 reels from vessels and transport (max weight 120T) with a total load-in tonnage of over 13,000T.

- In June, the Company celebrated the purchase of Pearson’s, located in Walker.

- In June, the Company announced its plans for a testing facility in the Dry Dock at Neptune Energy Park. The closure wall and partial infill of the dock involves separation from the drydock. Operating at a length of 56m, width of 38m and up to 12m deep, the Test Tank offers a volume of 25.5363 to the top edge of the tank. Construction of the new quay frontage extends 50m across the existing Engine Works Quay. The design of a new heavy load pad and heavy load routes permit the CC4800 Crawler Crane easy access to the Test Tank for a range of different projects.

- Between 2019 and 2020, Shepherd Offshore has completed demolition of over 1 million square foot of buildings and remediated over 100 acres at Halbeath Interchange, Scotland.

- In January 2021, the Company proudly announced ownership of the former Swan Hunter shipyard in Wallsend, North Tyneside. the 31.96-acre site includes two quays, two river berths, a wet berth facility and vacant former office buildings.

About Us

We are an established, innovative and driven organisation, working in partnership with employees, suppliers, local government and customers alike and we will stop at nothing to deliver the best solutions and expertise possible. Local teamwork, with global results.

The Company has strategically invested and developed local infrastructure which has directly attracted the Oil and Gas sector, Marine, Renewable Energy providers and Construction Industries to the Region & beyond. All supported and communicated through our many corporate values based on responsible regeneration and partnership working.

Latest News

-

Shepherd Offshore Proudly Supports Charity Football Match in Memory of Jordan Dolding and Michael Simpson

Shepherd Offshore and its team were proud to support a recent charity football match held in loving memory of Jordan... Read More

-

Shepherd Offshore Presented with a Certificate of Recognition

Shepherd Offshore was honoured to welcome Tratos representatives Prof. Maurizio Bragagni Esq OBE and Dr. Lorenc Xhaferraj to our Offshore... Read More

-

Ocean Survivoar – Shepherd Offshore Wishes Annasley Park Success in Her 2025 Ocean Survivor Challenge

Shepherd Offshore is delighted to extend its heartfelt support and best wishes to Annasley Park as she prepares for the... Read More

- © 2025 Shepherd Offshore

- Privacy Policy

- Website Use Terms

Website Cookies

We use cookies to ensure you have the best possible experience while using our website and to analyse how our website is performing. These cookies are safe and secure and do not contain any sensitive information and cannot be used to identify you. However, if you would like to change which cookies are used, you can click on the "Manage" button below. By clicking "Accept Cookies", you confirm that agree with our use of cookies and that you have also read our Privacy Policy and Website Use Terms, available in the website footer below. To read our Privacy Policy and find our more about our use of cookies, click on Learn More